Low-level Access Manlift

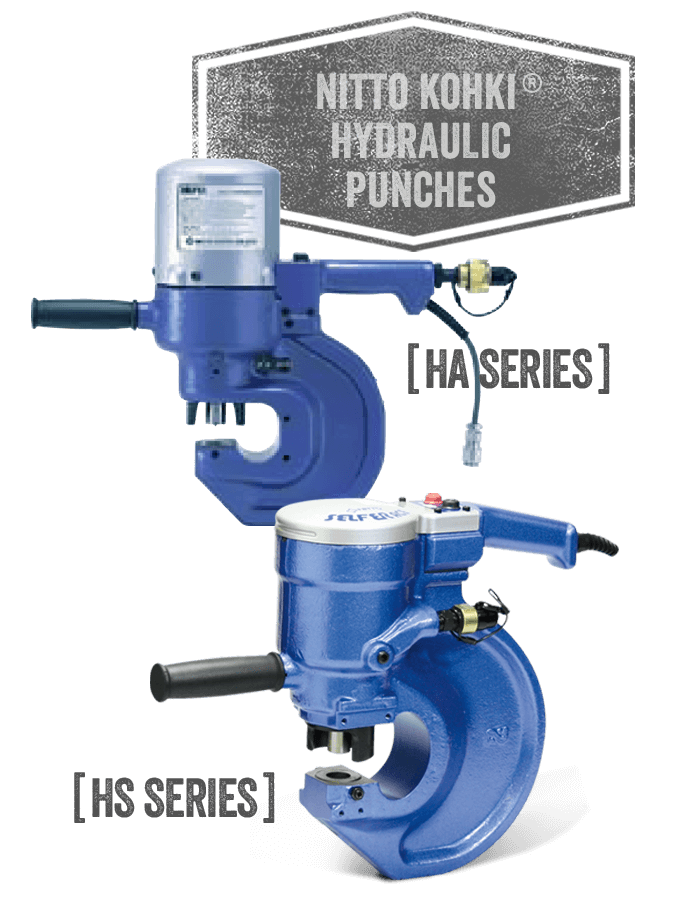

The best single-acting, portable hydraulic punch is one that you can trust. We offer a wide range of punches that are compatible with your application. Contact us immediately for any questions or suggestions. We will be happy to help you with your technical problems.

If you are in search of a great portable single-acting hydraulic punch with practicality and accuracy being your top priority, you’ve come to the right place. We have an intelligent range of punches eligible for your applications. Do not hesitate to contact us for requests and recommendations, and we are more than willing to handle your technical needs with utmost satisfaction.